ABOUT OAK FRAMES

What is traditional oak framing? What is it that makes our kind of traditional pegged timber framing different from other forms of carpentry and joinery? As well as those pegs mentioned above there are several features of oak frames that single them out visually to anyone who looks at one; the complex joinery, the girth of the timbers and the beautiful designs and curves in the frames and of course the natural qualities of the timber, the beautiful grain, the splits and knots and the wonderful colour .

But to the framer the defining features are in the method rather than the finished product, after all furniture and staircases can be made of pegged oak and curved timbers.

In order to understand this difference in method we should start with the fact that it is green timbe r which is used, mainly for reasons of economy, and that this timber moves and shrinks in a number of ways, even before the carpenter receives it, which makes it very difficult to connect accurately and therefore strongly. The problem is that all sorts of changes can take place in the short time that it takes to transport the wood from the mill to the framing workshop, for example it can bend, it can twist along its length and it can change shape, in section, from an exact square or rectangle to a parallelogram. There are also inaccuracies in the original milling to consider, so you can see that with all this going on, it may be quite tricky to connect two pieces of timber accurately and quickly.

r which is used, mainly for reasons of economy, and that this timber moves and shrinks in a number of ways, even before the carpenter receives it, which makes it very difficult to connect accurately and therefore strongly. The problem is that all sorts of changes can take place in the short time that it takes to transport the wood from the mill to the framing workshop, for example it can bend, it can twist along its length and it can change shape, in section, from an exact square or rectangle to a parallelogram. There are also inaccuracies in the original milling to consider, so you can see that with all this going on, it may be quite tricky to connect two pieces of timber accurately and quickly.

All other forms of carpentry rely on the regularization (squaring and straightening) of the timbers to allow the accurate marking out which is necessary to construct a framework to reasonable tolerances. Planing and thicknessing to ensure uniformity are used in most of these processes. Also in most systems such as conventional nailed stick framing, the timbers are thin enough that the carpenter can physically pull them into a straight line before fixing them.

None of this is possible with traditional timber framing. The timbers are too big to regularize except with huge four sided planers which are expensive, and they are also too big to be pulled manually into a straight line.

Therefore we need to find a way to make accurate joints and accurate frames out of irregular timbers. In a nutshell this is the real definition of green oak framing, it is a complex but quick method of making accurate things out of inaccurate pieces of wood. And because the process is relatively quick and uses “low grade” timbers, the cost of a frame is kept to a minimum.

There are three methods most often used to deal with these irregular timbers, scribe rule, square rule and mapping, with scribe rule being the most common in Britain and France. The actual methods employed, and the differences between them, are rather too complicated to describe in detail, but an overview of the scribe rule may be of interest, so I’ve made a separate “scribe rule” page which gives the general idea of the process involved.

The scribe rule is a traditional method which has its origins in the early medieval era, but which is as relevant today as it ever was. It may be possible nowadays, with the help of powerful machinery, to take a huge piece of green timber and make it perfectly square and straight, but it may not be desirable. Furthermore it will cost more both financially and ecologically and will not last long, the nature of green timber being anything but static.

For more on the aesthetic issues with movement and splits (shakes), see the 'shrinkage' sub page.

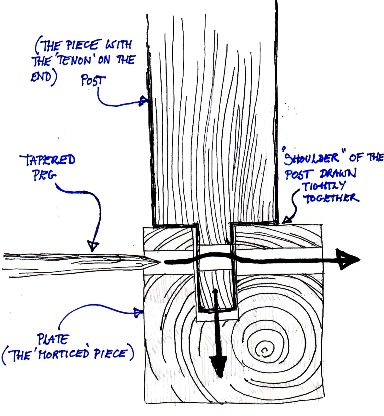

Draw pegging: Another defining feature of green oak frames in this part of the world is that most of the joints are draw bored. The sketch to the right is of a section through a mortice and tenon joint (tenon- male part, mortice- female part), draw bored and pegged with a drawn or tapering peg (known as a garron in Scotland). Draw boring is simply the offsetting of the peg-hole in the tenon by a few millimetres in such a way that a tapered peg, when driven through, will draw the tenon further into the mortice thus tightening up the joint. In effect it acts as a wedge. This does not work so well with dowel or turned pegs.

This pulling together of the joints in the frame makes for a much more rigid structure and helps to mitigate some of the problems associated with the movement and shrinkage of the green timbers.

Adaptability: A traditional timber frame is a very adaptable structure allowing easy changes of layout inside the building and lending itself to most types of design from towers to bridges, houses to pool covers and to almost any location.

The structure is made out of a relatively small number of components which carry the loads down to the foundations. This “point loading” quality means that clear spans can be achieved not only internally but also within each bay of the wall frames making extension of open living spaces easy.

The point loading and the lightweight nature of the structure, can help reduce foundation requirement s, thereby also reducing costs and carbon footprint significantly. Whole houses can be supported on foundation pads or piles which allows for easy builds on sloping sites where usually much digging, back-filling and the ubiquitous concrete are needed.

s, thereby also reducing costs and carbon footprint significantly. Whole houses can be supported on foundation pads or piles which allows for easy builds on sloping sites where usually much digging, back-filling and the ubiquitous concrete are needed.

The frames, being jointed and pegged, can be easily dismantled, yet, the structure assembled is so strong that if you could find a way of doing it, you could pick the whole thing up and turn it upside down and it would be none the worse for wear. More realistically you could easily dismantle the frame and reassemble it somewhere else to create a structure just as strong as it was in its original location.

More realistically you could easily dismantle the frame and reassemble it somewhere else to create a structure just as strong as it was in its original location.

Maximum spans for each roof frame type can be found in the “Frame Types” page.

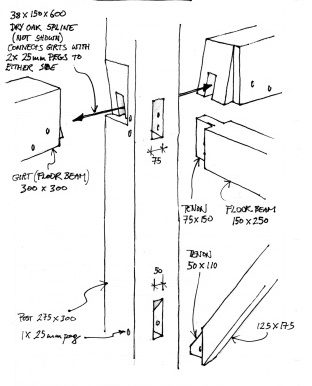

Useable Species: The four woods that are most often recommended by traditional framers are:

- OAK: Most durable and strongest. Also the most commonly specified. Moves and shrinks a lot.

- SWEET CHESTNUT : Also durable and strong but not commonly available except in the southeast of England. Can nevertheless be sourced. Splits easily but otherwise is a lot like oak.

- DOUGLAS FIR : (upper right) Moderately durable or slightly durable but strong and light. Much more stable than the others with low shrinkage. Easily available in very large sizes. Reddish color. Straight sections only, so impossible to design in curved bracing or other curved members

- EUROPEAN LARCH : (lower right) Moderately durable  and strong but can move a lot. Low shrinkage. Orangey color. Lots of it about so relatively cheap. Also predominantly straight sections available although given time curves could possibly be sourced.

and strong but can move a lot. Low shrinkage. Orangey color. Lots of it about so relatively cheap. Also predominantly straight sections available although given time curves could possibly be sourced.

The use of timbers other than the classic four mentioned above is possible within reason and if allowance is made for their weaknesses or vulnerabilities should be encouraged for ecological reasons. They are not usually available though in the sizes required so they would have to be sourced specially for a project which might take some time to achieve. The most suitable would be elm, beech, hornbeam, pine, cherry, and some other softwoods. I’ve built a frame of ash but it moves rather too much to be recommended.

A frame can be built using a number of different species in the same frame as was often done in the past, placing species in locations to suit their characteristics.

Durability: The heartwood of the timbers that are usually considered suitable for framing purposes all enjoy some level of durability (resistance to fungal and insect attack), which makes them  more or less suitable for use in situations with high levels of exposure to the elements. Oak and Sweet chestnut are the most durable, while Douglas fir and Larch are less well suited to high exposure conditions and whilst still moderately durable require different frame designs and or detailing if they are to be used in these situations. The heartwood (the darker core of the tree) comprises the bulk of the wood in a tree, as compared to the non-durable sapwood (the lighter looking juvenile wood) which surrounds the heartwood in a thin layer just under the bark.

more or less suitable for use in situations with high levels of exposure to the elements. Oak and Sweet chestnut are the most durable, while Douglas fir and Larch are less well suited to high exposure conditions and whilst still moderately durable require different frame designs and or detailing if they are to be used in these situations. The heartwood (the darker core of the tree) comprises the bulk of the wood in a tree, as compared to the non-durable sapwood (the lighter looking juvenile wood) which surrounds the heartwood in a thin layer just under the bark.

By using the right approach to design it becomes absolutely unnecessary to treat the heartwood of these timbers with any kind of preservative, indeed most of them are quite resistant to treatment anyway. The sapwood, a percentage of which is usually allowed in framing timbers, is not at all durable and can be treated if required but again in most situations this is not necessary. Woodworm can occasionally take up residence but it is usually too dry inside a house for it to achieve anything better than a sluggish lifecycle and it will usually die out quite quickly of its own accord. However a local surface application of a boron based insecticidal fluid will kill off any small infestations affecting the sapwood, which can occasionally happen, and which some people do not like to see.

The structural strength of the frame is in the heartwood which will last indefinitely as long as it is kept reasonably dry. There are thousands of green oak buildings around Britain that stand as testament to this, h aving lasted many hundreds of years. Leigh Court barn, on the right, is almost seven hundred years old (and particularly beautiful in my opinion) and there are many that are much older.

aving lasted many hundreds of years. Leigh Court barn, on the right, is almost seven hundred years old (and particularly beautiful in my opinion) and there are many that are much older.

There are some situations to be found within a building that can create enough condensation to be a problem even for oak, some of which are quite commonly seen and even recommended in modern building practice. An example of this is where a beam end is supported in a pocket in a masonry wall and in an attempt to prevent moisture reaching the timber a wrapping of DPC or similar impermeable material is specified. The problem is that this pocket can be quite a severe cold bridge and the result is regular condensation inside the wrapping, which can then not escape easily and may cause rot to set in. This situation is greatly exacerbated by internal insulation to the masonry wall, as often specified in refurbs and conversions.

Although the scenario above does not always result in a problem (as it depends on so many variables such as the airtightness detailing, the type of masonry in the wall, the render on the outside, the degree of exposure etc.) there are a number of solutions or risk reduction measures that can be applied to it.

These kinds of problems can be caught at the design stage and weeded out as the process goes along, but there needs to be good advice available, based on a deep understanding of wood and how it behaves. I can provide that advice as the project develops.

Fire resistance: On

the right is a wonderfully descriptive picture, of the aftermath of a fire in a

factory in the USA, which gives an idea of the performance of

timber in a fire. The horizontal timber beam is still strong enough to support the collapsed steel girders which have been weakened by the heat of the fire.

Although we have always burnt wood on our fires to heat our homes, oak being one of the favorites, modern timber buildings do not perform any worse than other types of building when it comes to meeting the fire regulations. This is because they are designed to meet the minimum periods of fire resistance by the architect and engineer. This fire resistance is achieved in conventional softwood stick frames by lining the timber element with plasterboard, installing cavity barriers and a number of other measures.

With a traditional oak frame, green or seasoned, this is not necessary, nor is any fire resistant coating or suchlike, even if, as is usual, the timbers are exposed internally or externally. To explain why I will quote one of the leading specialist oak frame engineers in Britain: "I am able to confirm that oak framed structures built to traditional techniques have excellent resistance to fire, and are capable of withstanding conditions either softwood or steel constructions never could. Oak will burn very slowly, and its charring actually acts to prevent further spread of flame, whilst not transmitting heat to other areas of the structure. The loss of timber due to charring to large sections of oak is well compensated for by its ability to withstand short term increases in stress, and unless sections are very small, they can withstand modern fire time standards without additional protection." Calculations to support this can be supplied to building control should it be necessary.

Frame tagging and other arcane markings: The characteristic carved numbering or tagging system one sees on these traditional frames is intimately tied in with the method of construction. This is because every piece of the frame has only one place in which it fits properly and it is important not to become confused when erecting the jigsaw puzzle on site. An indelible identifying mark is therefore an absolute essential. Most framers use the traditional system of chisel and or raceknife marks (a raceknife is a kind of hooked marking tool). It seems these carpenters marks have also become a favorite amongst frame owners because they highlight exactly the feature of green oak frames that most people would quote as the most attractive: the fact that you can really see what is going on with the structure, it is there exposed in the living space in all its pegged, hand made, glorious honesty. The tagging adds to this story telling you the order of assembly and even who cut this particular frame because every framers numbering looks slightly different. Just to confuse things the numbers are not quite the same as roman numerals with various different rules used by different yards or for particular frames due to their unusual shapes. Unraveling the meaning can be difficult at times!

An indelible identifying mark is therefore an absolute essential. Most framers use the traditional system of chisel and or raceknife marks (a raceknife is a kind of hooked marking tool). It seems these carpenters marks have also become a favorite amongst frame owners because they highlight exactly the feature of green oak frames that most people would quote as the most attractive: the fact that you can really see what is going on with the structure, it is there exposed in the living space in all its pegged, hand made, glorious honesty. The tagging adds to this story telling you the order of assembly and even who cut this particular frame because every framers numbering looks slightly different. Just to confuse things the numbers are not quite the same as roman numerals with various different rules used by different yards or for particular frames due to their unusual shapes. Unraveling the meaning can be difficult at times!

Normally a frame will have other marks scratched onto the timbers as well, such as 'plumb and level marks' which look like a long 'x' across the timber, or 'two foot marks' which look like an 's' bisected by a line. The reason they are scratched on is that, should the project be delayed at any point, they can not be washed off by the weather like a pencil mark. Thus the essential reference is preserved for use in later carpentry or on site during erection of the frame. Sand blasting usually obliterates these marks, but if the frame is not going to be sandblasted it may be necessary to consider this issue at an early stage. However most clients like them and the story they tell. After all these various frame markings are part and parcel of the tradition, and in conservation work often provide some of the biggest clues as to the history of a building. Normally my frames will be supplied with all these markings on the timber.

J. Rose Carpentry